Introduction

As the demand for sustainable food production grows, innovative greenhouse solutions are becoming essential. Fotoniq, a high-tech company specializing in advanced greenhouse coatings, has teamed up with Aranet to optimize light distribution in greenhouses. This case study explores how Fotoniq’s PAR+ coating and Aranet’s sensors are improving greenhouse operations.

Fotoniq’s PAR+ coating for glass greenhouses and Aranet PAR sensors for precise light monitoring in the greenhouse.

Fotoniq: Short Description of Company and Solution

Fotoniq recognizes the growing demand for high-tech greenhouses to meet the rising population’s need for sustainably produced healthy fruits and vegetables. Fotoniq offers a durable diffuse coating for glass greenhouses, designed to help growers increase production in an eco-friendly manner. This results in a balanced growth environment, improving efficiency, quality, and yield.

Technical Overview of PAR+ Coating:

- Durable Diffuse Coating: PAR+ optimizes horizontal and vertical light distribution and is the most durable spray coating available.

- High Light Transmission: The coating makes light diffuse while allowing for maximum light transmission, even on cloudy days.

- Year-Round Stability: By maintaining consistent light distribution, PAR+ supports a stable greenhouse climate.

Aranet solution: Accurate PAR Light Monitoring

Aranet PAR sensors play an important role in validating and monitoring the performance of Fotoniq’s PAR+ coating. By installing PAR sensors, data on light conditions and distribution within greenhouses can be obtained. Aranet platform allows for the evaluation of daily light integral and integrates with third-party solutions to automate light systems within the greenhouse.

Technical Overview of Aranet Sensors:

- Real-Time Data Collection: Continuous monitoring of light intensity, distribution and daily light integral.

- Wireless sensors: Easy implementation into greenhouse environment.

- User-Friendly Interface: Simple data analysis for growers.

Improving Light Conditions in Greenhouses

Fotoniq has developed a coating that significantly alters light & climate conditions across the greenhouse. Initially, the validation of these changes was limited to laboratory settings, making it challenging to quantify the effects in operational environments. However, the introduction of Aranet PAR sensors has proven crucial for Fotoniq.

“These sensors enable growers to visualize changes in light conditions, supporting Fotoniq’s two main claims: achieving a more homogeneous light distribution while maintaining high light transmission. This capability has greatly contributed to the success of Fotoniq’s projects and the validation of their product for new customers” says Gints Antoms, Global Business Development Director at Aranet.

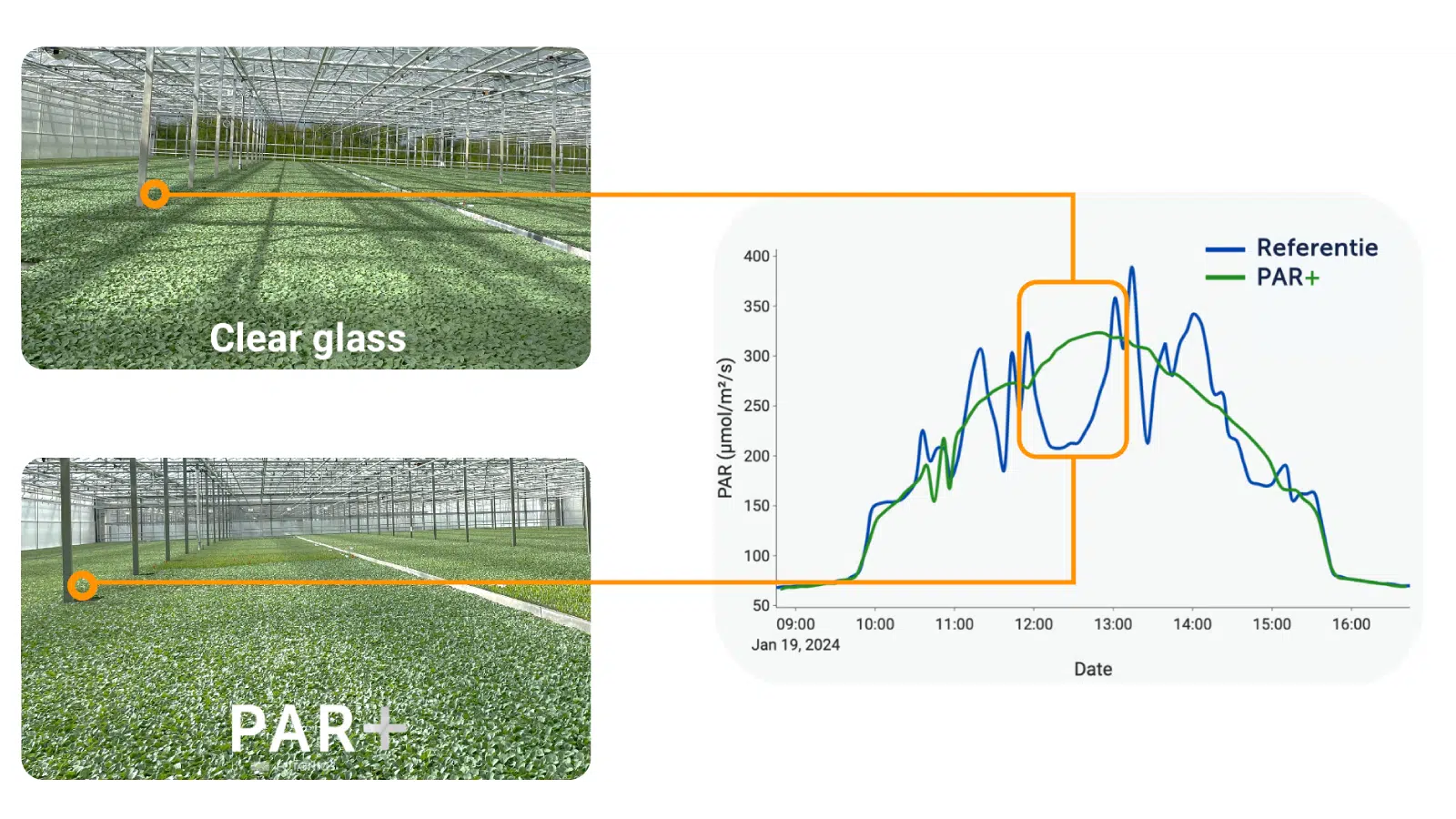

By implementing Fotoniq’s PAR+ coating and tracking light conditions in greenhouses with Aranet PAR sensors, shadows from construction elements are less pronounced, light intensity fluctuations are reduced, and plants experience less sun-related stress. The improved climate conditions result in an increase in efficiency, quality, and yield.

Comparison of light intensity fluctuations due to greenhouse construction elements between PAR+ coated area and reference area on a clear day – picture taken at Plantenkwekerij Gitzels B.V.

The solution has been implemented in greenhouses of various sizes and for different crops to validate the performance of the PAR+ coating. The results described in this case study are from greenhouses in the Netherlands:

1. Gitzels Plantenkwekerij Venlo Greenhouse – a total of 12 ha, starting material cabbage

2. Firma Verkade Tomaten Venlo Greenhouse – a total of 4.4 ha, tomatoes

3. NH Paprika Venlo Greenhouse – a total of 11 ha, Bell Peppers

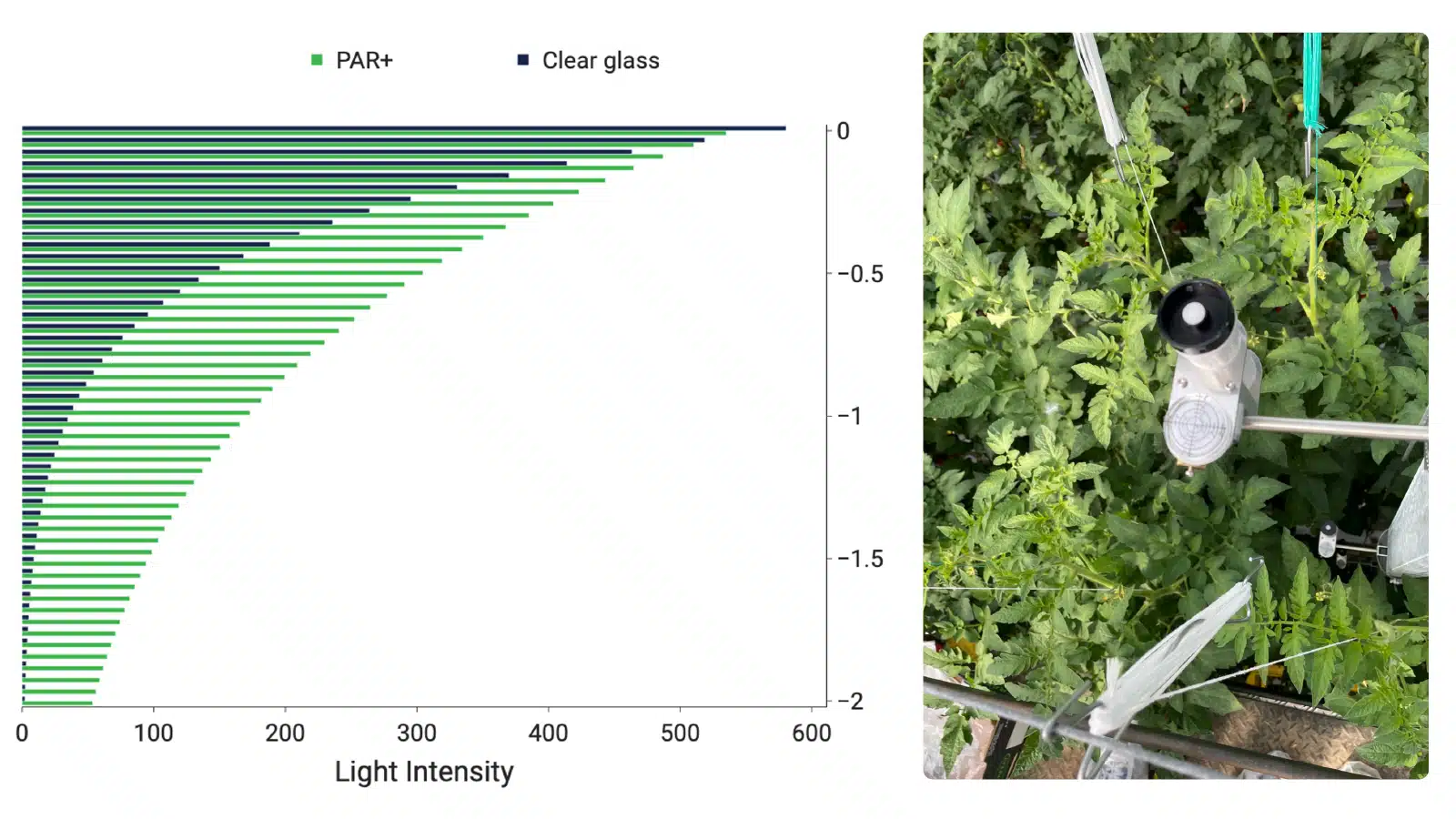

The figure shows collected data and Aranet PAR sensors installed in the greenhouses throughout

the projects at NH Paprika and Firma Verkade Tomaten.

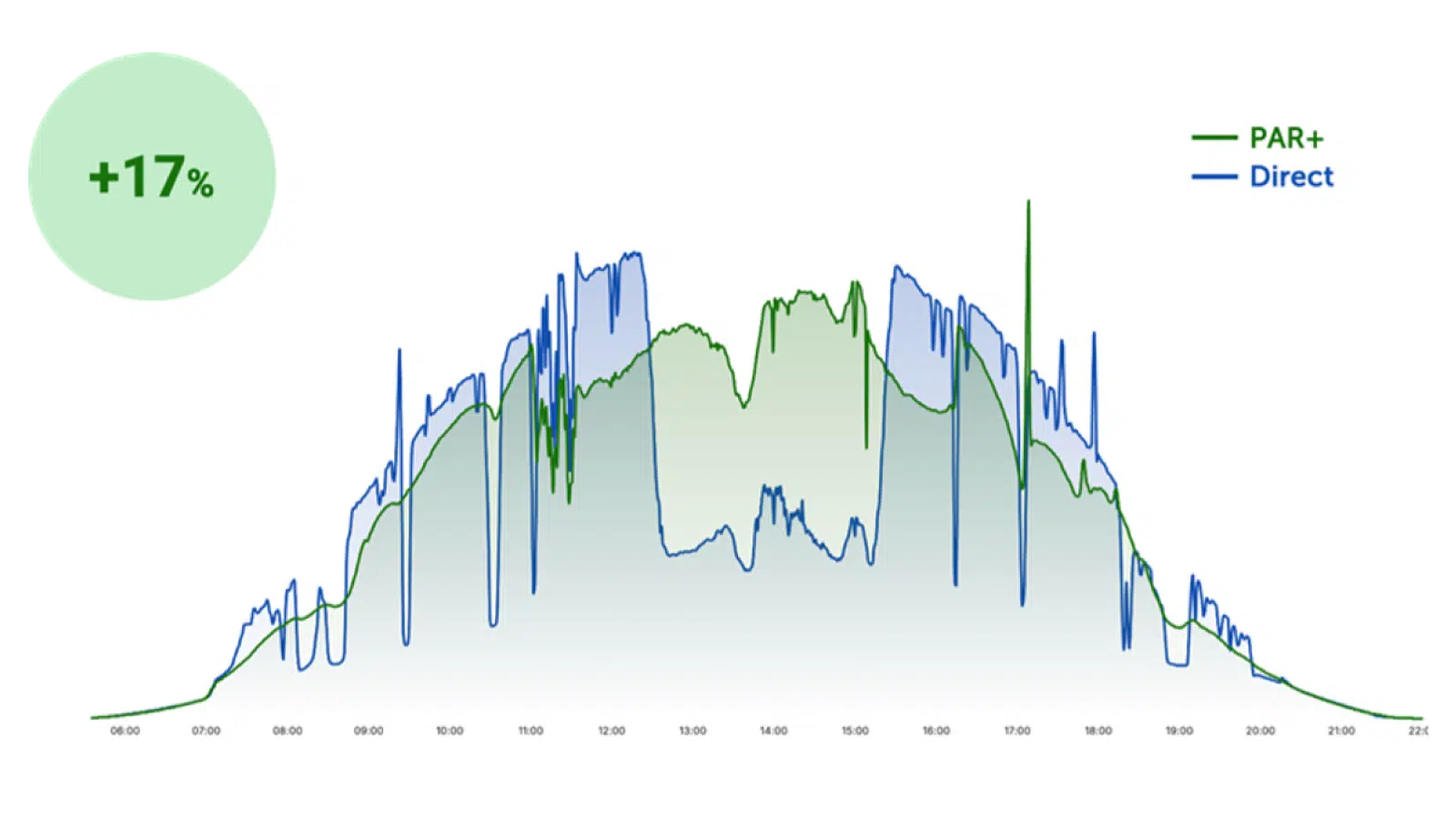

Reduced Sun-Related Stress on Plants

The PAR light monitoring process enabled tracking of reduced light intensity fluctuations caused by greenhouse structures. The coating created a more stable light environment, which reduced plant stress. Growers adjusted their screening strategies, allowing 17% more light into the greenhouse on sunny days.

NH Paprika reported, “The coating does its job, so closing the screens seemed unnecessary to me.”

PAR light data show more homogeneous light intensity after the coating implementation.

Deeper Light Penetration into the Crop Canopy

By installing several PAR sensors at various heights, Fotoniq was able to objectively measure light intensity levels at different heights of the plant. The diffuse light from the PAR+ coating penetrated deeper into the crop canopy, enhancing photosynthesis in the lower leaves. This increased the overall photosynthesis capacity, resulting in a 5.4% increase in production.

Firma Verkade Tomaten noted, “This was just a trial. If you coat the entire greenhouse, the differences will only be greater.”

The figure shows collected data and Aranet PAR sensors installed in the greenhouses throughout the projects at NH Paprika and Firme Verkade Tomaten.

Conclusion

The collaboration between Fotoniq and Aranet highlights the powerful combination of advanced coating technologies and precise monitoring tools. Supported by data from Aranet sensors, crucial insights were gathered objectively, providing evidence of improved light and climate conditions in the greenhouse. This enables both the grower and Fotoniq to learn how to optimize greenhouse settings in combination with the PAR+ coating to maximize efficiency, quality, and yield. This case study highlights the importance of data-driven solutions in modern agriculture.

For more information about Fotoniq’s solutions and how Aranet sensors can benefit your greenhouse operations, visit Aranet and Fotoniq’s websites. Or reach out to us at info@aranet.com & info@fotoniq.com